Every year I make my way through the wilds of the West Midlands to the NEC for the TCT show — which I consider to be the only 3D printing show worth visiting in the UK. Why? Aside from the free entry (which as a Scot is always important), TCT has it all, and is usually co-located with other industry shows that interest me as well (this year there was Interplas and PMMA). The TCT show is also a great place to catch up with people and get all the gossip – and there was a lot of that!

For the 2012 and 2013 editions of TCT I reported my findings here at 3DPI as “a new buyer.” This year was different. This year, for the first time, I attended the show as a 3D printer user. We installed a Stratasys uPrint in Spring of this year and, it must be said at the outset, the experience and knowledge that running a 3D printer brings changes your perspective somewhat.

So far, this year has seen as much, if not more hype in the 3D printing industry as 2013. The big players have consolidated purchases and started to filter some technologies from the high end to the sub $5k level. But what was interesting at TCT 2014 was the presence of the (relatively) new kids on the block. As you walked into the show MCOR and Blue Printer were very visible. A few years ago both of these were nowhere, yet now they had bigger (and better, in my opinion) stands than most of the established players. The machines themselves were pretty much the same as last year (albeit with incremental improvements) but the marketing message was certainly ramped up to max. To be fair, MCOR did the same last year, but I was surprised by Blue Printer – there is some serious marketing money behind them now.

Hot tip for a buy out this year? Blue Printer.

As we have a uPrint now I’ll be honest and say I skipped the Stratasys stand – well let’s be honest, the FDM side has stayed the same for years and to be frank, the stand was a bit dull with a random collection of Fortus, Objet and bits and bobs lying around the place. I’m sure the Connex3 is brilliant but really, if I want the information on that I’ll go to the service providers like IPF, who actually run the things.

Moving on, I stepped over to the 3D Systems collection of stands – which in all honesty (as someone who has designed trade show stands) also fell into the dreary category, with a random collection of machines and peripherals dotted around and the de rigour collection of 3D printed guitars and “twirly” vases. Now, I was hoping to see the mystical $5k CubeJet Colour Powder based 3D printer, or the CeraJet announced at CES in January – or at the very least some print samples from it – but all I was shown was the very nice little Cube 3 sausage machine and invited to have myself scanned on the Sense scanner. The thought of a 3D selfie was just too much for me to cope with, so I moved on with the only Sense being one of disappointment.

Fortunately all was not lost. I bumped into Richard Horne on the FormLabs stand. Great to see Richard, but also great to finally see the Form1+ platform in the flesh (so to speak) – and very nice it was too. My grand 3D printing master plan is to augment the uPrint with something for doing high resolution detailed parts, and the Form1+ seems to meet that goal. Good price, nice package and (finally) UK based suppliers. I was part way through my usual rant bemoaning all that was on display were arty pieces when us designers need to see real components, when they whipped out a very intricate medical prototype. Next year, put that stuff out front!

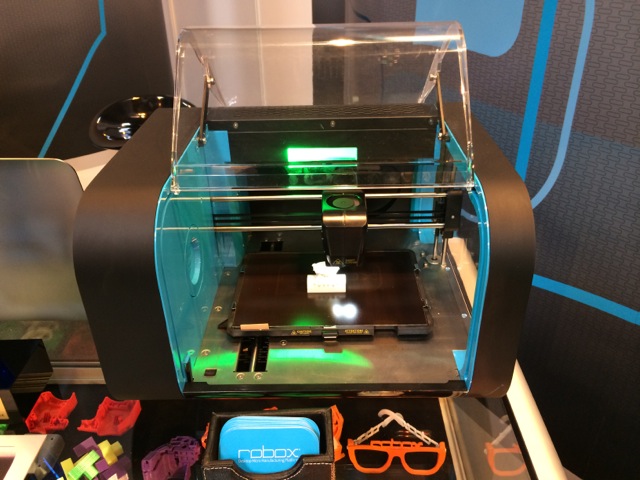

Next up was the CEL Robox 3D printer making its TCT debut. I’ve followed this one since it was announced on Kickstarter as it comes from a team that actually knows how to deliver high volume complex products – and it showed. Very well designed machine, good quality parts, lots of clever features and a great price. Furthermore, the future plans allow for expansion such as dual nozzles, paste type material and so on. All for £850.

I’ve not mentioned MakerBot yet. Frankly I’m not sure I can be bothered to either as they were by far the biggest disappointment. However, having used the uPrint now, I was very interested to see how it compared to the Z18 – aka – the big one. The 203 x 154 x 154 mm build of the uPrint is OK but, as they say, size matters. Well, having seen the Z18, to coin a phrase, it’s not how big it is, it’s what you do with it…and the Z18 doesn’t do it for me.

He showed me some 3D printed car thing saying “look at the quality”. I did. It was awful. I said so. The poor guy asked why. I said we get far better results on our uPrint. He said what layer height does that do. I said 0.254mm. He practically choked, eyes bulging exclaiming “we do 0.1mm!!”. I said layer resolution is just one factor in quality. He asked: “who makes the uPrint” (yes, really!). I said Stratasys. He said: “who is Stratasys?” (you couldn’t make it up!). I said, ask Bre.

In all seriousness, I’m not trying to be a troublemaker here, but my experiences with the MakerBot crew at TCT this year — and last year — have not been positive ones. Aside from the human interaction, the actual machine (the Z18) was a huge (no pun intended) disappointment. If you think these machines get anywhere near uPrint output, think again.

So, to regain some sanity, I decided to seek out a UK reseller and found Creat3D. Regular readers may recall that at TCT 2013 Rachel ruthlessly interrogated them about the infamous BotObjects 3D printer that Creat3D were supposedly going to be selling. Well, 12 months on I can report, unlike BotObjects, Creat3D has gone from strength to strength and grown considerably, as evidenced by a much larger stand showing the products they sell – which includes pretty much all the well known brands of consumer machines (but not BotObjects). However, the most impressive thing about this company is not the range of machines, but the knowledge and honesty of the staff. They told me the flaws of the various machines, and the compromises I would need to accept. MakerBot, take note!

So onto the real highlights for me:

DWS X-Fab. Put simply, despite the package FormLabs offers, the X-Fab is top of my list for an SLA type machine. I had a long chat with the guys on the stand and they explained the ins and outs of why the machine had not been launched yet (which I’ll not share here). However, when it comes out it will be a fully functioning package with a wide range of resins, UK distribution and so on. The parts it produces are stunning. FormLabs should probably take note.

MarkForged. I’ll be honest here and say that I did drop by for a quick peek at this 3D printer when I arrived at the show and thought “another sausage machine”, but after chatting to Al Dean (Editor of D3D) later in the day I revisited it and actually managed to speak to a couple of the guys about the technology and what they were trying to do, then it clicked. This printer prints standard PLA and Nylon, but it also prints Carbon Fibre and Kevlar Fibre in a continuous fibre. That makes the parts very stiff and very strong (albeit at a cost). But what really interested me was the way it does it. The print platform is designed for hot swapping, with microscopic repeatability. The software that drives it is not open source but a cloud based system that happens to be similar to something we are currently testing. The entry level to this package is relatively low cost but it opens a range of possibilities few others do.

Wacom. No, they don’t make 3D printers but I finally had the chance to try the full range!

There were, of course, many other companies on show. But to reiterate again, my outlook this year was a bit different for reasons already explained, so, most of the low cost FDM/FFF machines were bypassed quickly. The Makers area was full of interesting machines, and I am constantly amazed by the ingenuity of these guys — but it’s not for me.

What did interest me were materials. This ranged from various discussions on material suppliers stands to the inevitable “go on, break this if you can” from some SLS service providers. Despite all this, there are still some gaping holes in the 3D printed material options – nothing 3D printed can yet match a moulded glass reinforced nylon material, or a Polypropylene for flexibility. Trust me on this. I’ve broken plenty of parts this past year!

The metal industrial 3D printing fraternity were out in force again this year. Renishaw had a very nice mountain bike on show with its 3D printed titanium frame. Tucked away in a corner was Sciaky with their “welded” 3D metal printer system and some very large parts on show.

Speaking of materials, I popped into see Fripp Design and their 3D printed Silicone. This is one of the few companies offering an actual, proper material as opposed to a mimic or a version of “proper” materials. One to watch!

To sum up, TCT did not disappoint. Where the big two (I felt) could have pulled their fingers out and showed their new technology better, the smaller up and coming companies demonstrated that the industry is not all about hype, and are actually starting to become serious threats to the big two. Allied to that, companies like EOS were quietly there showing their wares, leading the more industrial end of the business.

All of which showed, to me at least, that the industry can survive the onslaught of consumer 3D printing hype. If I have one wish, it is that all people visiting TCT take a peek next door into Interplas to see some serious industrial machinery in operation – from moulding to automation. Arburg, a major injection moulding equipment manufacturer, had a huge automated moulding machine running, complete with pick and place robot….to make a single part. So when I hear people spouting nonsense about how household consumer 3D printers are the factories of the future I suggest they stroll around shows like Interplas to see what proper factory production equipment looks like.