In this, the second of a two-part interview with Rambod Radmard, the designer and creator of a new, innovative iPhone case that is currently on Kickstarter, Shane Taylor continues to ponder, along with Rambod, the value of 3D printing for prototyping applications.

Part 1 of this interview was published here on 3DPI last week.

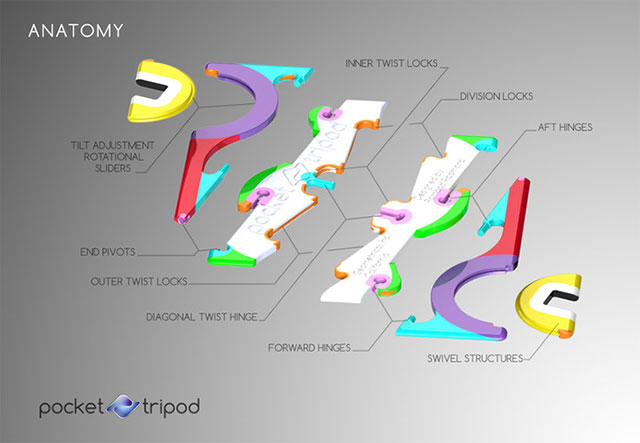

Now with USD$34,414 pledged of a $45,000 Kickstarter goal, and counting, the ‘world’s first iPhone stand that can articulate to any imaginable angle, and can transform to the shape of a credit card’ seems to be heading to success on it’s Kickstarter campaign. Rambod, the inventor of this intricate project, shares some more thoughts on the developments.

3DPI: 3D printing certainly facilitated a multiplicity of aspects of your project. What obstacles would you say stand in the way of producing a cheaper final version of the Pocket Tripod produced, extant, on a 3D printer?

RR: We want to make the Pocket Tripod reliable, and affordable. For that, the material needs to be durable, and the manufacturing shouldn’t cost more than what a customer would be willing to pay. As of now, even the best 3D printers can’t fulfill those requirements.

To print out Pocket Tripod, it takes roughly 45 minutes, compare this with injection moulding, which would take mere seconds. Of course high-resolution 3D printed materials also have a short life span, and won’t be able to handle any type of misuse.

3D printing is great for one-off products, but is still not there yet for mass produced consumer products.

3DPI. You mention inconsistency of 3D-printed output on such a finely tuned device as the Tripod. Was this easy to take in your stride during the R&D process?

RR: I think at the end of the day this was something that I had to deal with, and in all honesty, I was just happy that such an option even exists. Thinking of what a product developer had available to work with just a decade or two ago, I consider us to be lucky for having access to 3D printers.

The variation on quality did become irritating at times, but I learnt to get the information I needed from the results, and improve on my design regardless.

3DPI. Finally, what advice would you pass on to encourage others to step out of the mainstream, to the extent that you have, in product design?

Don’t get discouraged by obstacles that are presented by your unusual concept. Spend time on studying and improving it. Experiment with drastic changes on your design, and learn from the results. You’ll be surprised by how many new ideas this might give you, to help approach the obstacles and arrive at a solution.